Hydraulic Maintenance Tips: Prepping for Winter

As winter approaches, maintaining your hydraulic systems becomes more critical than ever. Cold temperatures can have a significant impact on hydraulic equipment, leading to potential failures, decreased efficiency, and costly downtime. Proper winterization and maintenance are essential to ensure your hydraulic machinery operates smoothly through the chilly months. In this blog, we’ll explore key tips for preparing your hydraulic systems for winter, emphasizing professional maintenance practices to safeguard your equipment.

Why Winter Maintenance Matters

Hydraulic systems rely on precise fluid flow and temperature control. During winter, low ambient temperatures can cause hydraulic fluids to thicken. This leads to increased wear and tear on components, sluggish operation, or even system failure. Additionally, exposure to moisture and freezing conditions can introduce leaks and damage seals. Therefore, proactive winter maintenance is crucial for extending equipment lifespan, maintaining safety standards, and avoiding unplanned outages.

Top Professional Tips for Hydraulic Winter Preparation

To ensure your hydraulic systems are ready for winter, consider these crucial maintenance steps performed by qualified technicians:

- Complete System Inspection: An experienced technician will examine hydraulic hoses, fittings, seals, and other components for signs of wear, leaks, or damage. Identifying issues early prevents more severe problems during cold weather.

- Fluid Analysis and Replacement: Hydraulic fluids should be tested to assess their viscosity and contamination levels. If fluids are degraded or incompatible with low temperatures, professional replacement with winter-grade hydraulic fluid is recommended.

- Fluid Filtration and Purity Checks: Maintaining fluid cleanliness helps prevent system blockages and corrosion. Filters should be inspected, cleaned, or replaced as needed by trained personnel.

- Ensure Proper Hydraulic Fluid Levels: Maintaining optimal fluid levels is essential for system efficiency. Technicians verify levels during inspections and top them up with the appropriate winter-grade fluid.

- Inspect and Service Hydraulic Filters: Filters are the first line of defense against contaminants. Regular servicing ensures clean fluid flow and minimizes wear during winter operations.

- Check Hydraulic Pumps and Valves: Cold temperatures can cause pump and valve components to become sluggish or seize. A professional inspection ensures these crucial parts are functioning optimally and are adequately lubricated.

- Drain or Protect Against Water Contamination: Water in hydraulic fluid can freeze, causing damage. Technicians remove accumulated water or install boots or covers to prevent moisture ingress.

- Test System Pressure and Flow Rates: Adjustments may be necessary to compensate for temperature-related viscosity changes. Using calibrated equipment, professionals optimize pressure settings for winter conditions.

- Lubrication and Seal Inspection: Ensuring all seals and lubrication points are properly serviced prevents leaks and maintains system integrity in cold weather.

- Implement System Warm-Up Procedures: Professionals recommend implementing standardized warm-up routines before heavy use, reducing stress on cold components.

Essential Winterizing Checklist

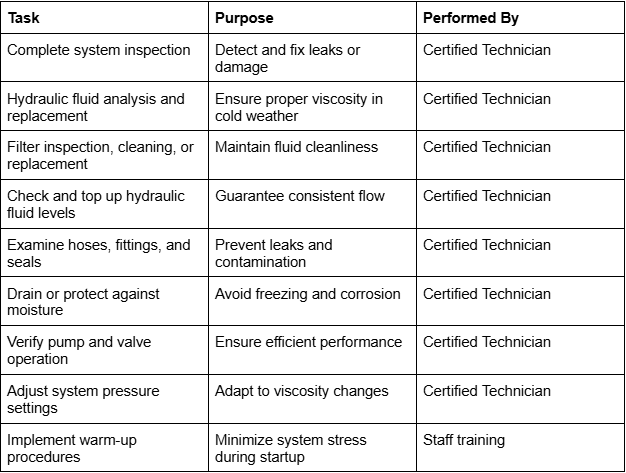

A comprehensive winterization plan includes both operational and maintenance considerations. Here’s a table summarizing key tasks:

The Impact of Professional Maintenance in Winter

Engaging certified technicians for hydraulic winterization ensures that all system components are operating under optimal conditions. Professionals have access to advanced diagnostic tools, enabling precise assessments and tailored solutions for your equipment. Investing in expert maintenance reduces the risk of unexpected breakdowns, extends machine lifespan, and promotes safety during winter operation.

Prepping Hydraulic Systems Is Complex

Preparing hydraulic systems for winter isn't merely about adding antifreeze or performing superficial checks. It’s a comprehensive process that involves detailed inspection, testing, and servicing by qualified professionals. By following expert tips and adhering to a thorough maintenance plan, you can minimize downtime, prevent costly repairs, and ensure your hydraulic equipment remains reliable throughout the cold season. Remember, proactive winter maintenance not only safeguards your machinery but also enhances safety and productivity in your operations.

Do Your Hydraulic Systems in Kankakee & the Chicagoland Area Need Winterization?

If you manage vehicles or machinery with hydraulic systems in Chicago, Bedford Park, IL, or Merrillville, IN, contact us at Miller Hydraulic. We’ve been helping local businesses maintain and winterize their hydraulic systems since 1991.