What to Do If a Hydraulic Pump Malfunctions

Hydraulic systems are integral to many industrial, manufacturing, construction, and automotive operations. They power machinery ranging from excavators and forklifts to manufacturing presses and aerospace equipment. Given their critical role, a hydraulic pump malfunction can cause significant downtime, costly repairs, and safety hazards. Recognizing the signs of trouble and knowing the appropriate steps to troubleshoot and resolve the issue can save time and prevent further damage. Here’s a comprehensive guide on what to do if you suspect your hydraulic pump is malfunctioning.

Recognize the Signs of a Hydraulic Pump Malfunction

Before jumping into troubleshooting, it’s essential to identify the symptoms indicating a malfunction:

- Reduced or Erratic Pressure: A drop in hydraulic pressure or fluctuations can impair machine performance.

- Unusual Noises: Whining, grinding, or banging sounds often signal internal issues or cavitation.

- Overheating: Excessive heat generated by the pump may indicate a malfunction.

- Fluid Leaks: Visible leaks around the pump suggest seal failure or internal damage.

- Vibration or Jerky Movements: Irregular operation can result from internal wear or debris.

- Slow Response or Lack of Movement: This may point to pump failure or clogged lines.

If you notice any of these signs, it’s crucial not to ignore them. Prompt action can prevent minor issues from escalating into major repairs.

Immediate Safety Precautions

Before inspecting or working on the hydraulic pump, prioritize safety:

- Turn Off Power: Disconnect or shut down the machinery to prevent accidental activation.

- Relieve System Pressure: Hydraulic systems operate under high pressure. Use designated valves or relief mechanisms to safely depressurize the system.

- Wear Appropriate PPE: Safety glasses, gloves, and protective clothing are vital when working on hydraulic equipment.

Diagnosing the Issue

Once the system is depressurized and safe, conduct a systematic check:

- Check Hydraulic Fluid Levels and Condition: Low or contaminated fluid can cause pump failure. Top up or replace fluid as needed.

- Inspect for Leaks: Examine hoses, seals, and the pump itself for signs of damage.

- Examine the Hydraulic Filter: Clogged filters can restrict flow. Clean or replace them if necessary.

- Review System Pressure: Use pressure gauges to verify if the pressure reading aligns with specifications.

- Listen for Unusual Noises: Identifying the source of noise can help locate internal problems.

Troubleshooting Common Problems

Depending on your findings, here are some common issues and how to solve them:

- Cavitation: Caused by a fluid shortage or air in the system. To fix, check the fluid levels, eliminate air leaks, and ensure proper inlet conditions.

- Seal Damage or Leaks: Replace worn or damaged seals to prevent fluid loss and contamination.

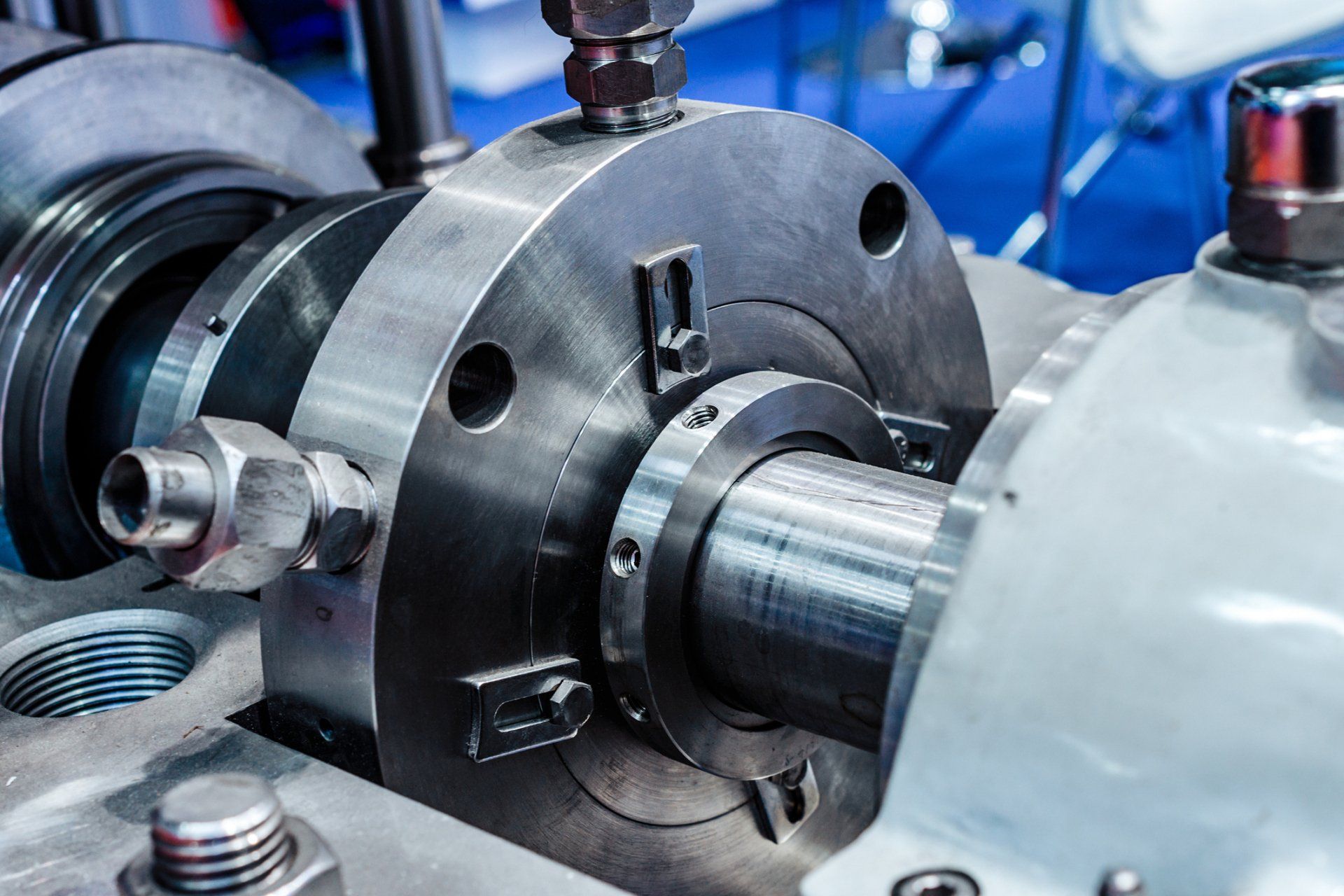

- Worn or Damaged Internal Components: Bearings, gears, or vanes may need replacement if worn.

- Blocked or Restricted Lines: Clear debris and obstructions from hoses and filters.

- Overheating: Ensure adequate cooling, check for excessive load, or verify that the pump is the correct size for your system.

Preventive Maintenance Tips

To minimize the chances of future malfunctions:

- Regularly Check Fluid Levels and Quality: Replace hydraulic fluid according to manufacturer recommendations.

- Perform Routine Inspections: Look for leaks, wear, or damage.

- Maintain Proper Filtration: Change filters regularly to prevent contamination.

- Monitor System Pressure and Temperature: Use gauges to track operational parameters.

- Follow Manufacturer Guidelines: Use specified parts, oils, and maintenance schedules.

When to Call Professionals

Some issues require specialized knowledge or tools. If troubleshooting does not resolve the problem or if internal repairs are needed, it’s wise to contact a qualified hydraulic technician. Attempting complex repairs without proper expertise can damage the system further or pose safety risks.

Do Your Hydraulic Systems Need an Inspection in Central or Northern IL or NW Indiana?

If you have a

hydraulic system in

Kankakee,

Gilman, IL,

Lowell, or

DeMotte, IN, and suspect it is in need of servicing,

contact us at Miller Hydraulic. We’re locally owned and have been the area’s experts in hydraulic equipment since 1991.