Serving All of Central & Northern Illinois and NW Indiana

Office: (815) 468-7745

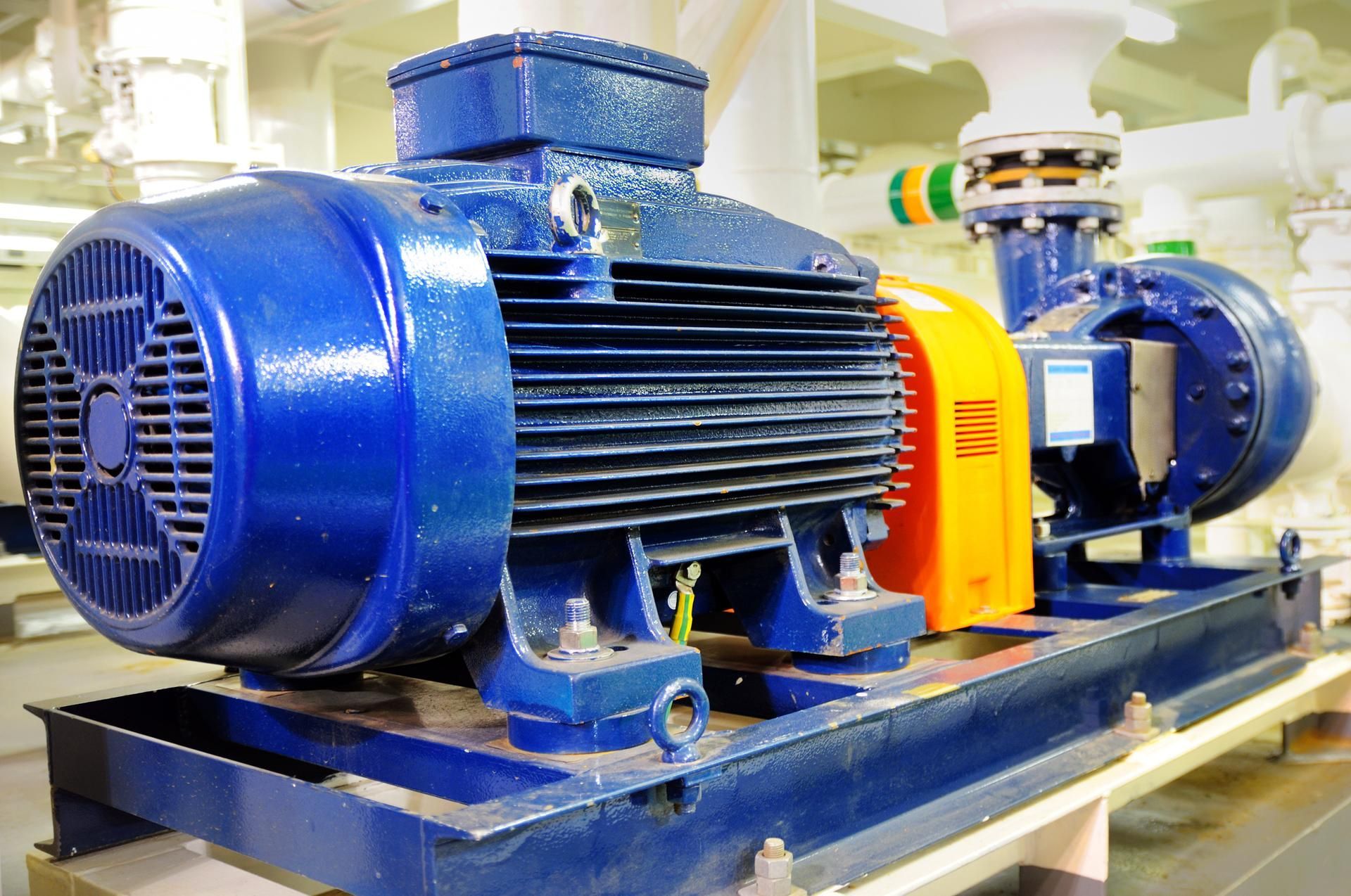

How to Choose the Right Hydraulic Pump

Hydraulic systems are the heart of numerous industrial and commercial applications, powering everything from heavy machinery to automotive equipment. At the heart of these systems lies a critical component—the hydraulic pump. Non-compensated hydraulic pumps are positive displacement, which means that the same amount of oil comes out with each revolution. Danger! Do not plug the discharge port, or you will break something expensive.

The efficiency and performance of hydraulic systems hinge on choosing the right pump. With multiple factors to consider, making an informed decision is imperative. This blog will guide you to select the perfect hydraulic pump tailored to your needs.

Understand Your Application Needs

Before delving into the intricate world of hydraulic pumps, it's imperative to embark on a journey of comprehensive assessment regarding your application's unique requirements. Factors such as flow rate, pressure, and system size are the vital parameters that will govern the choice of the pump that best suits your needs.

Neglecting to match your pump selection with these specific demands can lead to potentially dire consequences: either under-sizing, which results in system inefficiency, or over-sizing, causing unnecessary costs and energy consumption. The first step is calculating your hydraulic system's required flow rate and pressure. These parameters serve as the cornerstones of your pump selection.

Consider Efficiency

Efficiency is a pivotal aspect of hydraulic systems, as it directly influences energy consumption and the system's overall performance. When striving to make an energy-efficient choice, meticulous research into the efficiency ratings of different pumps is indispensable. Seek pumps that skillfully strike the equilibrium between power input and output, finely tailored to your specific application.

Efficiency in hydraulic systems is all about conserving energy and optimizing performance while minimizing heat generation. Choosing a more efficient pump can lead to significant cost savings over time. Energy-efficient pumps contribute to sustainability and reduce operating expenses, making them an excellent choice for cost-conscious individuals and organizations.

Reliability and Maintenance

Reliability is paramount when it comes to selecting a hydraulic pump. Opt for a pump with a well-established track record of dependability. Particularly in industrial settings, downtime due to pump failures can result in high costs and disruptive setbacks. To mitigate such risks, it is essential to thoroughly investigate the manufacturer's reputation and the pump's history of reliability.

A pump that is easy to maintain saves time and minimizes operational costs in the long term. Regular maintenance is the lifeline of any hydraulic system; it ensures prolonged functionality and guards against unexpected breakdowns that can harm your operations.

Budget and Cost of Ownership

Budget constraints are a reality for most projects, and this is where the intersection of financial considerations and hydraulic engineering becomes especially crucial. When evaluating hydraulic pumps, it is crucial to consider the initial upfront cost and the long-term cost of ownership. The latter includes maintenance expenses, energy consumption, and potential replacement costs.

While there may be a temptation to opt for the least expensive option initially, it's imperative to strike a balance between your budget limitations and the performance requirements of your application. Investing more in a higher-quality and more efficient pump can often lead to substantial payoffs in reduced operating costs and improved system performance. High operating costs and the potential need for frequent replacements can quickly outweigh the initial savings of a less expensive pump.

Pump Types and Their Advantages

Hydraulic systems rely on different pump types, each with its unique advantages. Gear pumps are simple and reliable, ideal for moderate-pressure applications. Vane pumps offer quiet operation and versatility, making them suitable for fluctuating loads. Piston pumps excel in high-pressure scenarios and come in various designs.

To make an informed choice, comprehend these pump types' characteristics and performance capabilities and select the one that best aligns with your specific application's demands. Your pump choice can significantly impact the efficiency and effectiveness of your hydraulic system, so careful consideration is essential.

If you need expert guidance in selecting the perfect hydraulic pump for your needs, contact us at Miller Hydraulics Service, Inc. Our team of experienced professionals is ready to assist you in making the right choice for your hydraulic application.

CONTACT INFORMATION

Address: 1965 E. Amberstone, Manteno , IL 60950

Office: (815) 468-7745

Emergency: (815) 405-4042

Email: miller-hyd@comcast.net

Business Hours:

- Mon - Thu

- -

- Friday

- -

- Sat - Sun

- Closed